DRY ICE BLASTING

What is Dry Ice Blasting?

Dry Ice Blasting is an environmentally responsible process and can help companies adhere to their environmental policy and chemical use targets.

Dry Ice Blasting is a clean and safe method of cleaning.

Dry ice cleaning has been approved by:

- Environmental Protection Agency (EPA)

- Food and Drug Administration (FDA)

- US Department of Agriculture (UDSA)

- Food Standards Agency (FSA)

Dry Ice media blasting is a technique that can be used to clean equipment and property in a way that is environmentally advantageous and it has minimal impact on the surface being cleaned.

Contaminants are removed from the substrate by the impact of the Dry Ice crystals. The particles compresses, and mushrooms out, creating a high-velocity snow flow that flushes the surface. The dry ice shears and lifts the contaminant off the surface with no damage and leaves no residual waste. This shearing or lifting force is caused by the sublimation (transition direct from solid to gas) of the dry-ice particles resulting in a sudden 800-fold increase in volume of the gas directed along the plane of the substrate.

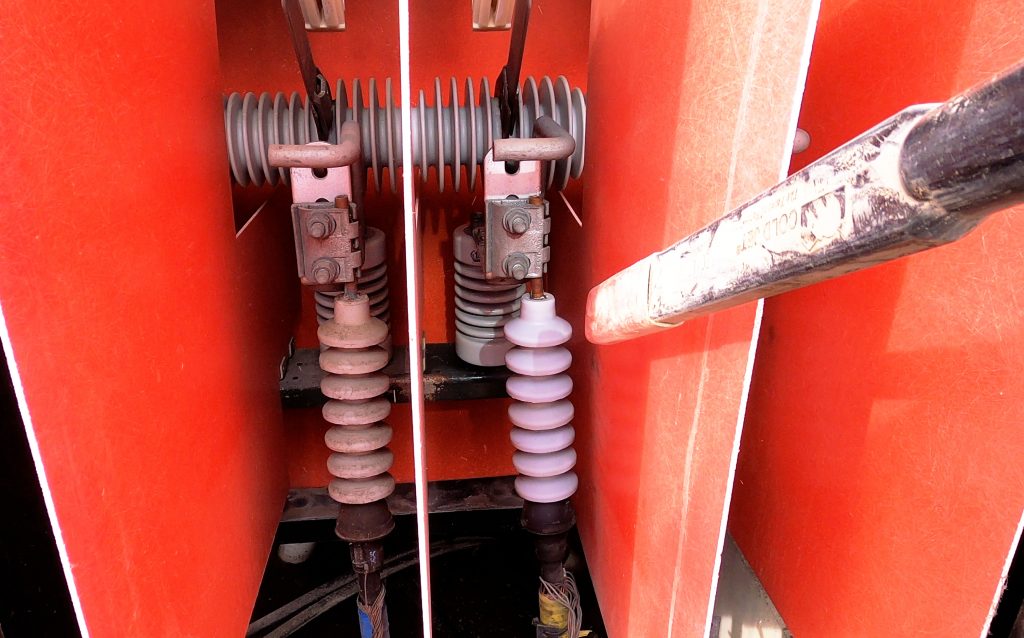

This unique property means that the dry ice blast medium simply disappears, leaving only the original contaminant to be disposed of. In addition, cleaning in water sensitive areas (e.g., in the vicinity of electrical cabinets) is now practical. CO2 gas is an insulator with a dielectric strength of 72kV/inch. It is ideal for work in and around underground enclosures.